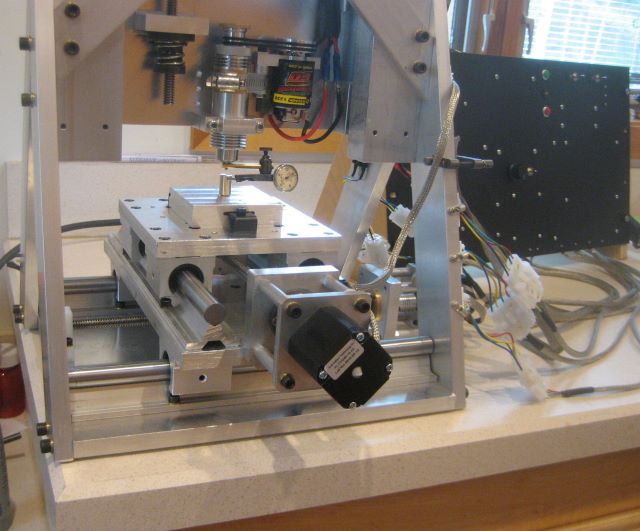

For the engraver Y axis, I have made a temporary limit switch bracket of wood, and wired a relay to change the travel direction at each limit.

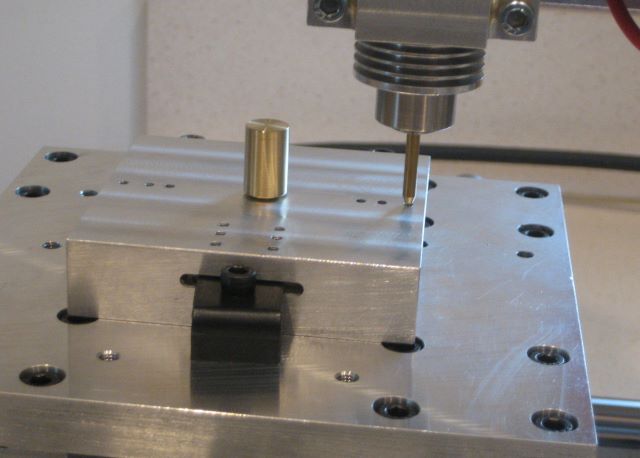

As initially assembled, the NEMA 17 stepper would move the table smoothly at 1.0 amp current limit. But during the first 4 hours of operation, the motor increasingly labored. I raised the current limit to 1.2 and then to 1.4 amps, but it was obvious that this was not successful operation.

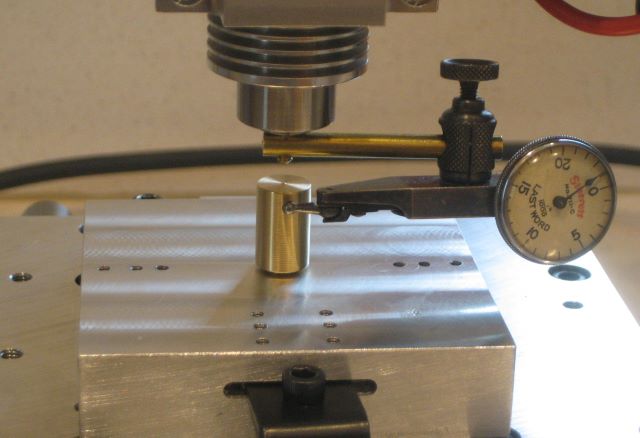

The problem was that as I made the nut and thrust parts (for the first time), I had not thought out the sequence of machining operations well enough. So part surfaces were not parallel enough, or perpendicular enough, for smooth running. I made the necessary corrections and in the process changed two of the thrust parts from natural acetal to teflon filled acetal (i.e., Delrin AF).

The slide now ran smoothly at 0.8 amp current, but not at 0.5 amp. At 0.8 amps, I then ran 100 hours continuously, travelling the acme nuts more than 5000 feet. During this run, the space between the two nuts increased by no more than .002 inch. So I am quite satisfied with the wear rate.

Rotation of the thrust assembly requires more torque than for the anti-backlash nut assembly, and I thought that the Delrin AF thrust parts represented an improvement over natural acetal. So I have now re-made the plastic parts of both assemblies in Delrin AF.

My intention is to briefly run these parts and then decide between natural and teflon filled acetal.

A note on acetal components: when I first tapped the two acme nuts, they each felt like they closely fit the acme screw. This is in contrast to a brass nut, for which the clearance in the standard acme thread can be felt. I believe that the apparent absence of clearance is due to plastic “flash” at all the sharp corners of the thread. During the first few hours of nut operation, this material is turned into loose debris and the nut then has normal clearance. So a spring loaded assembly is needed to obtain zero backlash, despite the initial feel of the plastic nuts.

Update 9 Dec 2015: I ended up doing a 100 hour test on the Delrin AF nut also. Again, the total wear of the two nuts did not exceed .002 inch. I have no reason to think that there is a difference between natural acetal and Delrin AF, for this application.