The 4 jaw chuck is a workhorse for reelmaking. Sherline’s 4 jaw is just big enough to hold the 2.5 to 3 inch diameter material needed to make reel frames. Since these parts have to be machined from both sides, the independent movement of the jaws allows re-centering to any measurable degree of accuracy when the work is turned over. And, work can be shifted from lathe to mill (with rotary table) while centers are maintained.

I have been having some difficulties with my 4 jaw chuck; I could not get the two faces of a chucked part parallel. There would often be .002 or .003 difference in thickness from one side to the other. I was aware of the problem for a long time before I realized (duh…) that the problem was in the chuck.

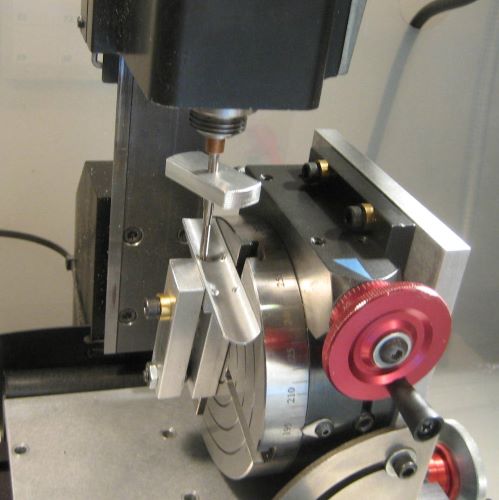

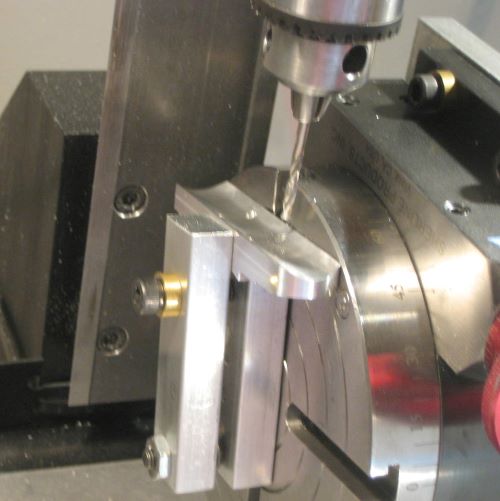

Holding a 3 inch diameter part requires the jaws to be installed in their “reverse” position, and the material disk then rests on flat surfaces of the chuck. Here I have set up a Last Word indicator to show the height of these flats. I can turn the spindle slowly by hand and get a sequential indication of height. For my chuck, three of the jaws were in close agreement, but the fourth was about .004 higher than the others.

The jaws here are of course loose and may not be at the same relative heights as when the chuck is tightened on a part. Regardless, .004 is more error than should exist. I took the chuck apart and re-assembled twice, but got the same error each time. Further, it was easy to see that material with the first side flattened would “rock” on the jaws when turned over.

Fred at Sherline agreed that this was beyond the Pale, and suggested that I send it back for re-grind. He waived the repair charge even though my chuck was out of warranty.

When I got the chuck back, I saw that Sherline had assembled the jaws in “normal” position and run them to the center so that they all were tight during grind. Now my indicator setup showed that they were all within a .001 inch band, even when I put them in “reverse” position and they were loose.

So here is part of the education of an amateur machinist; learning to recognize when the equipment is out of spec and can easily be fixed.