For several months I have been building an engraving mill and not producing any reels. So now I am back on reels, and have to re-familiarize myself with the processes. At the center of the reel is a critical part made of Delrin. It is the bushing for the spool, and it is one piece with the wheel of the clicker.

I have been calling the toothed part a “ratchet”, but that may not be correct. Dictionaries say that a ratchet allows just one direction of rotation. A clicker has to allow bidirectional rotation, but the drag may be biased.

Although the teeth are cut with an “involute gear cutter” it is not really a gear either, since it does not mesh with anything.

I managed to scrap 3 parts before producing a useable bushing/clicker wheel. So here is a photo record to help me the next time I do this part.

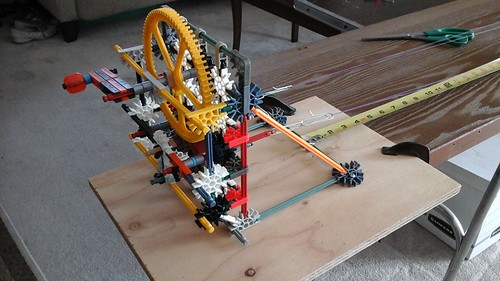

This is the simple fixture that I use, just a piece of shaft material drilled and tapped at one end, plus a clamp screw, washer, and spacer.

First I make a cylindrical blank that is .015 or .020 inch longer than the finished part.

The fixed spindle for the reel is .250 inch diameter. I drill the blank with a .250 diameter drill.

When a brittle material like metal is drilled, the hole is likely to be a little larger than the drill bit. But when drilling a tough material like Delrin, the hole is little smaller than the drill bit.

So when I push the fixturing shaft into the new hole, it is a firm fit.

I next turn a .900 inch diameter (a little smaller than the gear dedendum circle) for a length of .97 inch, just .01 inch shorter than the shank of the finished part.

So far, concentricity of diameters has not been critical.

But the gear OD has to be concentric with the bore. So I re-do the press of the part on the fixture, letting the shaft protrude from the toothed end.

Then I center the fixturing shaft in a 4 jaw chuck.

The gear OD can then be turned concentric with the shaft.

My 4 jaw chuck will mount to the mill’s rotary table, but the adapter may not bring it to center. So I check runout on the rotary table, and adjust the chuck as needed.

The teeth can then be cut.

The finished gear teeth are “fuzzy”, due to the toughness of the material.

I can then remove the fixture and ream the bore.

This reamer is 6.4 mm diameter, or .252 inch. Like a drilled hole, the reamed hole is a little smaller than the tool. It is a good running fit to a .250 diameter spindle.

At the toothed end, I then trim the part to final length.

This removes some of the “fuzz” from the gear teeth.

In preparation for turning the shank diameter, I again center the mandrel (the fixturing shaft) in a 4 jaw chuck.

Since reaming, the part slips easily over this mandrel.

At this point, I measure the bore of the mating spool.

My spool drawing calls for a .4375 inch reamed bore, but the truth is that my Sherline lathe does not have enough low speed torque to make this. So I have to use a boring tool, somewhat less accurate. Also, the spool is anodized, which reduces its bore.

I turn the shank of the part so it has .001 to .002 inch interference with the spool bore.

Here I am facing the other side of the gear teeth, removing the last .01 inch extra width.

The recess can then be cut.

This particular boring tool works well on Delrin when moved radially with the cross slide.

Finally, I give the gear teeth a haircut. This nipper is a “desprue” tool from Micromark.