The click mechanism for my reels mounts to the reel backplate by three posts; two are spring pins and the third is a pivot for the pawl. For some time now, I have fastened these by custom made screws. For a neat appearance, I have recessed the screw heads into counterbores. More recently my reel backplates are too thin to accommodate the counterbore, so I have installed the posts by press fit. But sizing the pin of the fit is tedious, and not always successful. I decided to try riveting, which is a typical process for commercial reels.

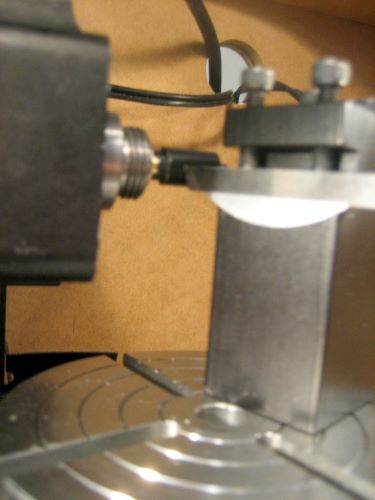

Here is a pressing anvil for a 1/8 inch tubular rivet (AN450), a homemade rivet, and a brass sleeve for the anvil. The sleeve lets me use my arbor press rather than purchase the special squeezer tool.

For the rivet I chose c544 phosphor bronze as a compromise of machinability and formability.

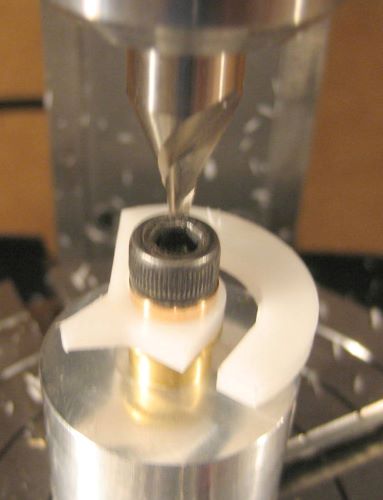

And here is the rivet installed on a scrap of aluminum. The forming is neat, no split.

One problem is a slight anvil impression on the aluminum. It may be that the arbor press allows me to apply excess force, so I need some practice.

Later: Indeed, a little care while squeezing avoids any marks on the substrate.

21 Dec 2013: Considering electrochemistry, what rivet material is suitable for an aluminum substrate? High strength alloy 7075 splits when formed. 6061 is just marginal, on the edge of splitting. The solution seems to be grade 2 titanium.

Note: Tub Rivet Die SM200-4504