In 2015, I replaced my Sherline mill with a MiniMill (Little Machine Shop 3990).

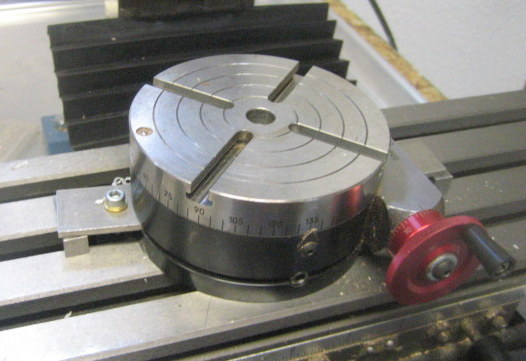

The switchover was simple; I only had to make some special hold down clamps to continue using my Sherline rotary table with the new mill.

Now I have gone a step further and bought a MiniLathe. I chose MicroMark 84631 because it has 20/inch leadscrews on the cross slide and compound.

I locate the cutting tools by reading the dials at the handwheels, and I cannot work with a dial that has 62.5 divisions.

During lathe assembly, my attention was drawn to the system for adjusting the carriage gibs. It uses a combination of screws to push and pull the gib. None of these screws can be properly tightened because there is no solid stack of parts to tighten against.

So I removed the “push” set screws and put round shims under the gib and around the “pull” cap screws.

The tool post can clamp a bit as large as 5/8 inch, but you would have to do a lot of grinding to get the point down to the right height. I have many 1/4 inch bits from my Sherline lathe that I will continue using.

The brass shim here brings a 1/4 inch bit up to working height, and the shoulder centers the bit under the clamping screws.

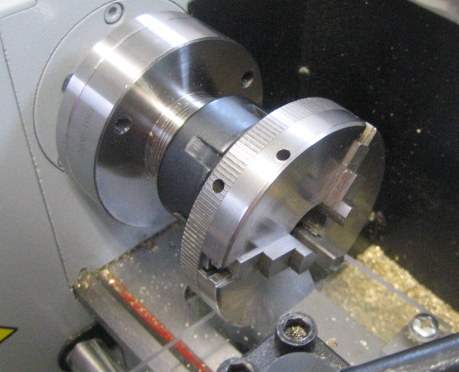

It is obvious that the 3 inch chuck for the new lathe is more robust than the Sherline 3 jaw chuck.

But this extra heft comes at a price. Changing chucks is a matter of fiddling with studs and nuts in a confined space, rather than just spinning the chuck onto a spindle nose thread.

Further, I am heavily invested in Sherline chucks.

Significantly, the 4 jaw chucks can serve as milling vises, and can be quickly transferred to the rotary table on my mill. So I am highly motivated to continue using my Sherline chucks.

My solution is to buy an ER-32 collet chuck from Little Machine Shop. This allows me to chuck stock of up to 3/4 inch diameter through the hollow spindle.

When I first installed the collet chuck base on the spindle, I found the TIR on the taper to be about .0001 inch. Then I chucked a gauge pin and read about .0002 inch TIR. (Note 9 April: Apparently this was luck. The second bolt-on measured .002 TIR on the taper. Later same day: I made several installs. One position consistently has .002 TIR, another .001, but the best position is under .0003 .)

The key to using my Sherline chucks is to leave the ER-32 chuck in place and make an adapter with the Sherline 3/4-16 thread.

This adapter is Duronze. It has 3/4 inch OD and a bore of a little more than 1/2 inch. Sherline sells a similar adapter but it does not have a bore.

Here is the adapter installed.

And here is a Sherline chuck mounted.

To keep chips from falling where they may, I tape transparency film to the stock chip guard and I have installed a piece of acrylic sheet in front of the carriage.

Note also a piece of Tygon tubing (split) around the exposed lead screw.

From LMS I bought several accessories: Jacobs chuck, live center, die holder, hand crank, and cut-off tool.

With all this, I believe that I have replaced all the Sherline lathe functions except for knurling.