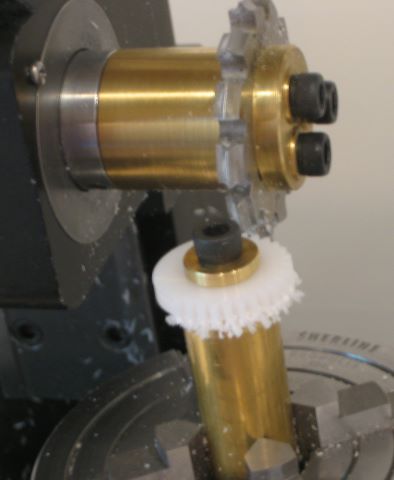

When I made my first reel design, I had to find a way to make a serviceable ratchet. First there was the problem of what material to use; this blog has several post on material testing. But there was also the problem of cutting the teeth of what looked a lot like a gear.

Wholesale Tool then had some close-out specials on “Involute Gear Cutters”, and I bought several of these that were for 36 diametral pitch, 20 degree pressure angle gears. This is the type of cutter that comes in a set of 8 to cut gears of the full range of tooth numbers.

My ratchet was to have 30 teeth, so at first I used the #4 cutter, correct for gears of 26 to 34 teeth. Later, when I realized that involute profile is not important for a ratchet, I started using the #8 cutter, designed for 12 and 13 tooth pinions. This cutter rounds off the tooth tip a little better. In ratchet-pawl operation, the flank of the pawl repeatedly impacts the corners of ratchet teeth, so round tooth corners reduce the impact stresses. This is different from gear action, where involute profiles mesh.

(Aside: As I understand the 8 cutter system, the #4 cutter is correct for 26 teeth, and has “acceptable error” for 27 to 34 teeth. This point is relevant to gear cutting but not to ratchet cutting.)

Update 24 June 2013: I have stopped using the #8 cutter when making ratchets of 20 to 30 teeth.

When indexed at smaller angles than 360/13 = 28 degrees, the two involute profiles on the sides of a tooth actually meet at a diameter less than the ratchet OD that is desired. I am now using whatever cutter is appropriate for the actual number of teeth in the ratchet.

I chose to buy 20 degree pressure angle cutters instead of 14.5 degree for two reasons. First, it was the 20 degree cutters that were on close-out sale. Second, the 20 degree profile is a little rounder than the 14.5 degree profile because 20 degree is generated from a smaller base circle.

Once I had a working prototype reel, I made a complete drawing set. This set can be purchased at The Eclectic Angler.

Anyone trying to follow these plans has a bit of a problem when it comes to the ratchet, however. I did not know it at the time, but English cutters (based on diametral pitch) are almost always 14.5 degree pressure angle, and metric cutters (based on module) are almost always 20 degree pressure angle. The cutters that I got from Wholesale Tool were an oddity. Nowhere on the Internet can I now find 36 DP, 20 degree cutters.

In case anyone is stymied by this problem, I offer the following several solutions.

1. Buy a gear

SDP/SI has acetal gears based on diametral pitch but with 20 degree pressure angle. The closest diametral pitch is 32. Choose a 26 tooth gear and the pitch diameter is then 0.8125 inch, a little less than the 0.8333 in my design. So the center distance of pawl to ratchet must be reduced by about 0.010 inch. Also, the pawl tip can be 0.005 wider because the space between teeth is 0.0491 (vs. 0.0436 in my design).

These gears need modification: cut out the hub and reduce the face width.

2. Cut a gear with a 14.5 degree cutter

In this case, the total included angle at the pawl tip should be 29 degrees instead of 40 degrees. If you do not change the pawl, you may find that the pawl jams between gear teeth when spool direction is reversed.

3. Cut a gear with a module cutter

You can find 0.7 module (metric) cutters of 20 degree pressure angle from several sources. This is a diametral pitch of 36.28 per inch diameter. A 30 tooth gear has a pitch diameter of 0.8268 inch, or 0.0066 less than the 36 pitch gear in my design. Compensate by reducing center distance from ratchet to pawl by 0.003 inch.

4. Use a 60 degree V groove cutter.

You will want a 60 degree angle at the tip of the pawl also. Be sure to adjust pawl length so the ratchet-pawl set can pass “over center” when spool direction reverses. The tooth tip corner will be quite sharp, so it would be a good idea to round it off a bit. Perhaps a second pass with a 90 degree V groove cutter would work.

5. Grind a single tooth cutter

Sherline sells a one tooth gear cutter (P/N 3217), for which you grind the end of an HSS tool blank to the shape of the space between two teeth. This is a good approach; you do not need an accurate involute to make a ratchet, and you can round the tooth tip as much as you want.

6. Machine a single tooth gear cutter, then harden it

There is a YouTube showing this process. The involute profile is approximated by a circular arc.

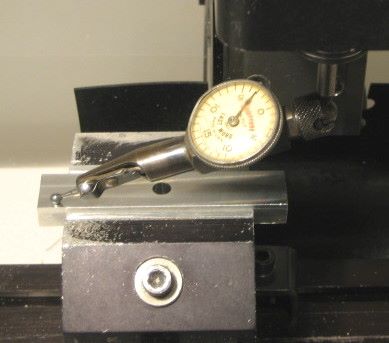

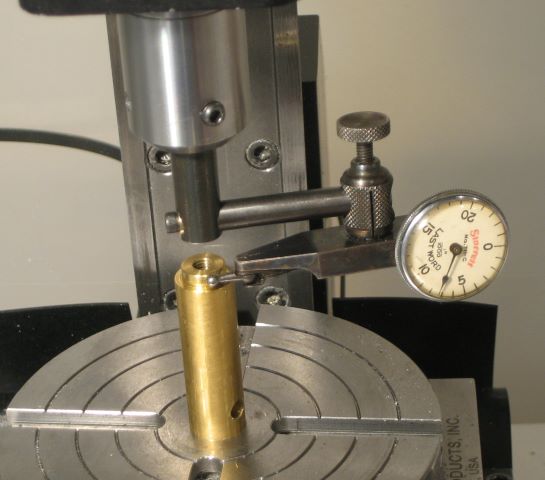

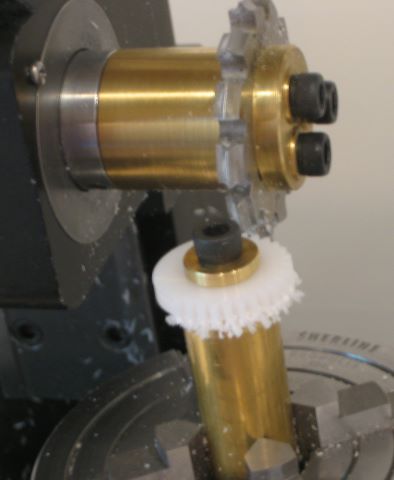

Here I am cutting teeth on an acetal (Delrin) blank. I am convinced that a plastic ratchet is superior to a metal ratchet because a properly chosen plastic is tough whereas metal is brittle. The toughness causes a small problem when cutting teeth: a shaggy looking gear when you are done. It takes more time to clean up the teeth than to cut them.

Update 16 Jan 2013: Finally found a source for DP sized gear cutters with 20 degree pressure angle, http://mdmetric.com/prod/meda/medatoolsupply/columnar4950.html?cat_id=9608&&category_site=MEDATOOL

Update 22 Nov 2014: Here is an updated link

Click to access 2_chapter-pages.pdf

See page 152 for 20 degree pressure angle cutters based on diametral pitch.

Update 26 Oct 2017: I have recently tried to order from mdmetric.com and find that they are totally unresponsive. Apparently they carry no stock but instead make a custom order to some supplier of theirs for tooling. But here is another source that appears to carry stock: KBC Tools .