In a post of 6 July 2012 (“ER16 Collet Set”), I reported on a collet set that I had acquired. These were different than many collets familiar to machinists in that they were saw cut from both ends in such a way that they could contract about .040 inch in diameter, allowing just 10 collets to cover the range of 3/8 inch down to less than 1/32 inch. The collets need a holder of some type, and this set provided a holder that fit the MT1 tapered bore of my Sherline lathe headstock. At first glance, the set seemed work well, but later I noticed that I could not get consistent TIR. In many instances, TIR would approach .0100 inch. This in spite of many efforts to exclude stray metal particles from the mounting interfaces.

Now, I think that I am able to measure TIR. I use a Starrett “Last Word” indicator, see post of 5 May 2012. The needle swings of this indicator can be read down to .0001 or .0002 inch. When I chuck a gauge pin in a Sherline milling collet, I always get about 0.0002 inch TIR. This is what a collet should provide. When I chuck the same pin in my 3 jaw scroll chuck, the TIR is about .0030 inch, and this the same time after time. (I have so far resisted the temptation to start grinding the chuck jaws.) But with the ER16 collets and their MT1 holder, I see anywhere from .0010 to .0100 inch TIR. So I have shyed away from using the collet set, as I cannot depend on a small TIR. I speculate that the reason that the TIR is sometimes as small as .0010 is that error in the collet fit to the holder and error in the MT1 fit will sometimes cancel.

Recently I saw a different MT1 holder on offer through on-line auction. Instead of using the MT1 bore of the headstock spindle, it fits the 3/4-16 external thread at the nose. This is a big advantage in that it leaves the spindle bore open and thus allows work with longer rod stock.

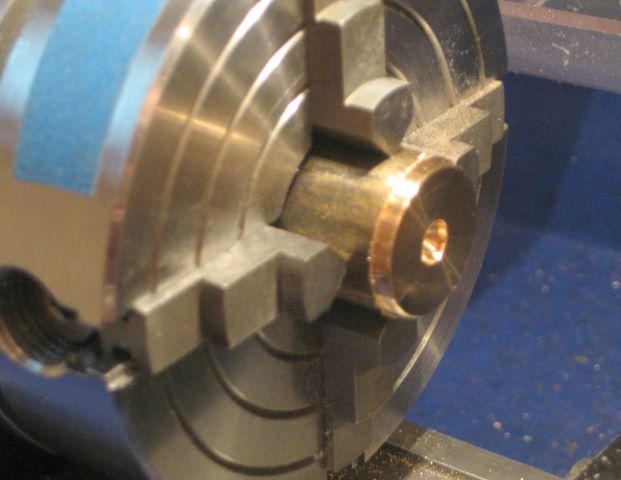

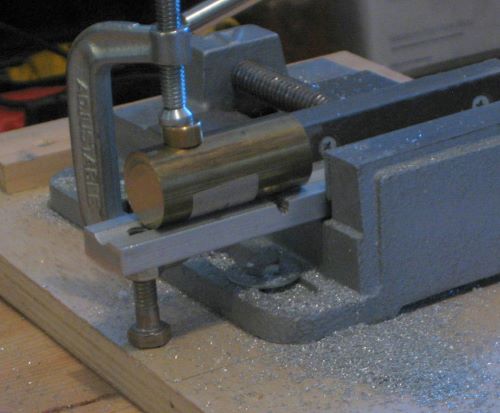

Hoping for better performance than I get with the MT1 holder, I ordered one. This is it, along with one of the collets from the original set.

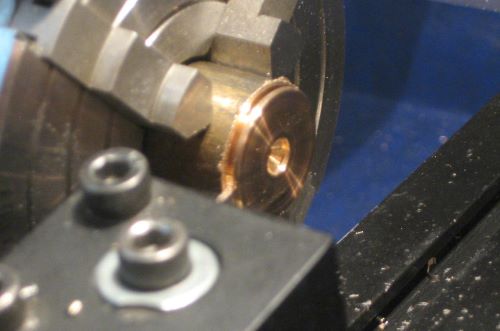

And here I am measuring the TIR on a chucked gauge pin.

It was a big disappointment. TIR was consistently in the .0080 to .0110 inch range through several disassembly/reassembly cycles.

So my conclusion is that ER16 collets provide a good grip on a cylindrical surface, but cannot be expected to give the TIR of more conventional collets.

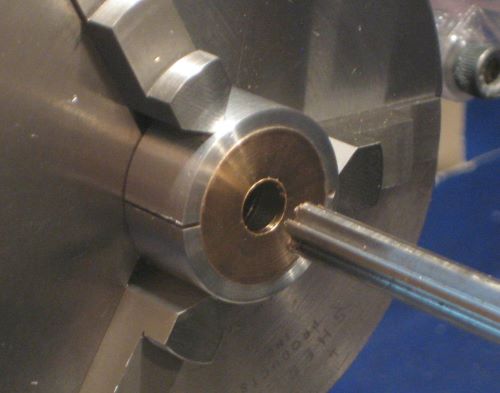

Certainly some of the fault lies in the manufacture of the collet holder. Here I am measuring .0055 inch TIR on just the tapered bore.

Sherline is able to get vanishingly small TIR on items such as their 3/8 inch end mill holder; this item should be as good.

Update 7 Jan 2013: This morning I took another look at the original MT1 collet holder. I installed it four times into the spindle, and measured TIR of 0.0005 to 0.0008 on the tapered bore. But each time when I added a collet, clamping nut, and gauge pin, the TIR on the pin would be 0.0018 to 0.0040. This indicates that most of the problem is with the collets rather than with the MT1 holder.

Update 18 Jan 2013: It is possible that my collet set is poorly made. To examine this possibility, I ordered one collet from another source. But it showed a similar inconsistent TIR on a chucked gauge pin. So I conclude that the ER collet design is inherently incapable of providing the TIR of conventional collets.

Update 21 Jan 2013: Reader Leroy suggested varying the angular position of holder to spindle and collet to holder as a way to minimize TIR. And he was right, I can get 0.0004 or less TIR on a gauge pin if I fiddle around with relative angular positions. Hopefully, I will be able to scratch/engrave/etch some permanent reference marks on the several parts and eliminate the search.

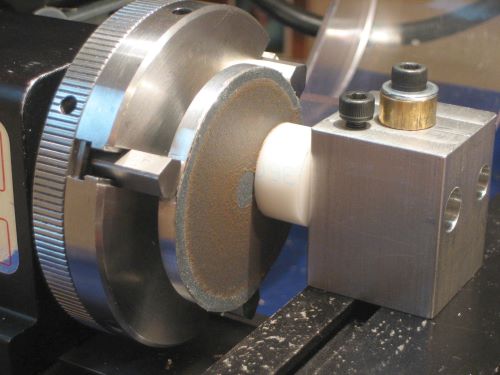

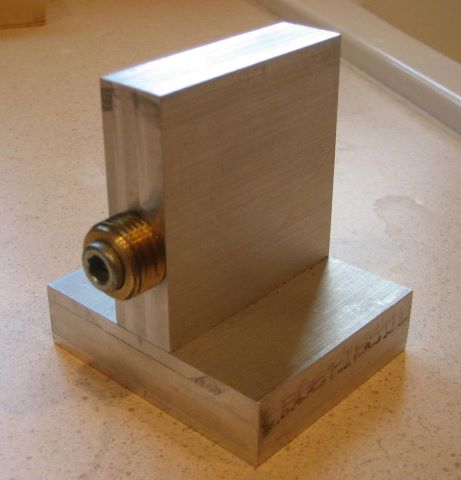

My attention at the moment is to make a different holder for the collets. The MT1 holder, when properly “clocked”, is achieving small TIR, but I want a holder that has a 10 mm passage through so I can chuck long stock (that is, like the collet chuck described above but running on the center of my spindle).

A improved ER16 collet chuck appears in a blog post of 30 Jan 2013.