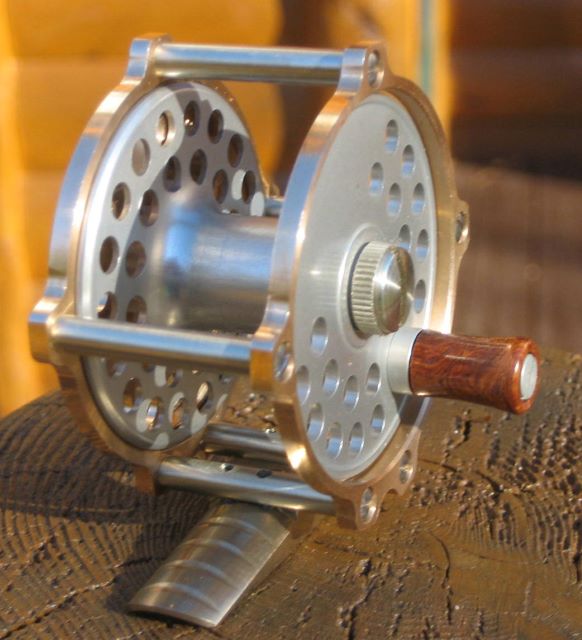

I made this ferrule set from Duronze (c642 bronze). Duronze is perhaps the next best thing to drawn nickel silver, and probably better than machined nickel silver. It is size 11 (11/64 inch) for a 3 weight rod.

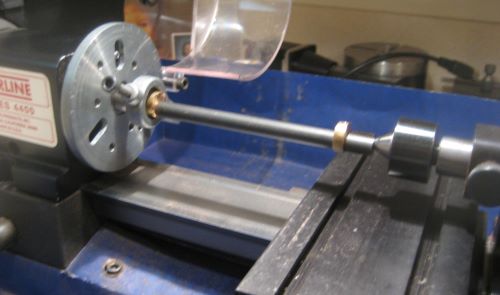

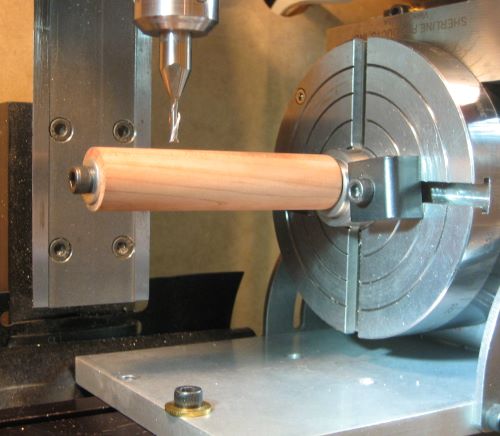

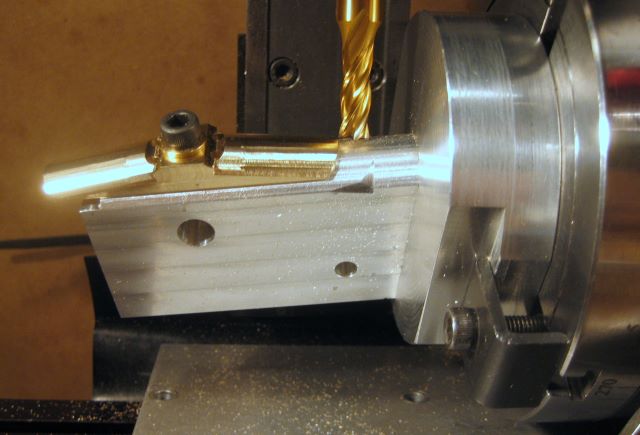

These are straightforward lathe parts: turning, drilling, reaming. I only used my mill at the last step, to saw the six slots. Many rodmakers already have Sherline lathes and use them for various rod finishing operations. They might also like to turn ferrules, so I have been trying to imagine a fixture for the lathe that would hold a ferrule in 6 positions while sawing.

Update 8 Sept 2014: Mark S. has asked for further details. He is one of those who finishes rods with a Sherline lathe and would like to do more.

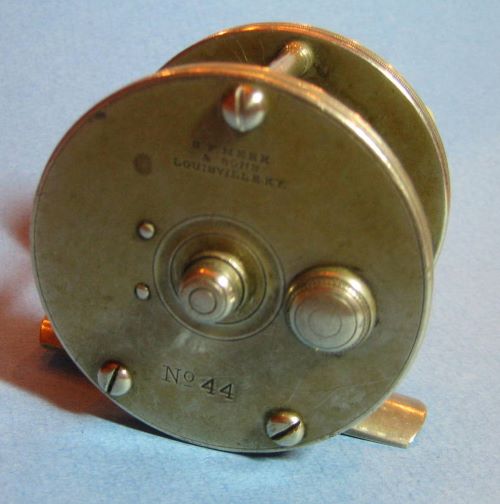

Tutorial: The only instructional information that I have seen is Bogart’s ferrule presentation at 2013 Grayrock. This is available at the Grayrock web site. But this info is for drawn NS ferrules. So here is some additional info on machining ferrules. I am no expert at this point, the photo above is my first effort. And these haven’t been used yet on a rod.

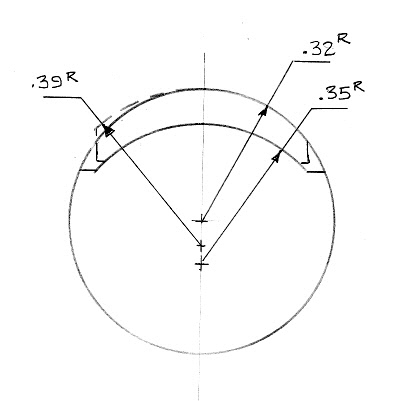

Dimensions: There is a Excel spreadsheet that you can find by Googling “step down dimensions”. These are what I used, except that I needed to provide 11/64 for the bamboo at the male end as well as at the female. So the male here is 1/64 oversize at the bamboo end.

Duronze: You can buy c642 bronze from On Line Metals or from McMaster-Carr. Minimum diameters are 3/8 and 5/16 respectively, so it is a little more convenient to go with McM.

Work holding: You will find collets more satisfactory than a chuck, it seems to me that the part is more rigidly held. And a collet that lets you feed stock through the spindle is a real plus. I use an ER-16 setup that I have blogged about. Use the “Categories” list at the right (Tools – Work Holding) to locate my post on “Improved ER-16 Collet Chuck”.

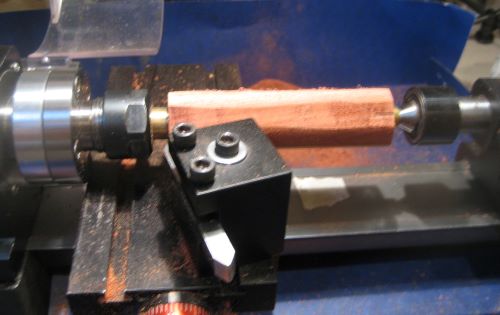

Turning tools: A brass type HSS tool is the right thing. It has a round nose and no top relief, so it is very easy to grind from a blank. Look at the McMaster catalog page to see the shape. I recommend that you grind it yourself, because Duronze quickly takes the edge off a turning tool and you must frequently re-sharpen. The long skinny rod deflects while turning, so it is easy to end up with a taper. Do some lathe filing to remove the taper. When approaching the final diameter (plus .001 or .002) on the male slide, I use a 4 cut pillar file. Be sure you know how to read the .0001 vernier of a micrometer.

Drill bits: Like brass, bronze wants to “grab” your drill bits. I bought some special bits for brass from McM and I think that they are somewhat better than the standard bit. You only need 3 for one size of step down ferrule, or just 2 if you do not step down. While drilling, back out frequently to clear chips.

Reamer: You will want to ream the female slide. The Ebay store Zorotools has a suitable 11/64 reamer for just a few dollars. I drilled about .006 undersize before reaming. Go slow, back out a few times and let the work cool off. The Sherline M0 tailstock taper just cannot handle the torque. Cleaning M & F tapers with alcohol helps some, but I keep a narrow open end wrench handy for extra boost. The standard end wrench is too wide; my solution is a special wrench that bicycle mechanics know about, for removing pedals from English bikes. (See thinwrench.com or Ebay, 9/16 size.)

Lapping the female slide: Read Bogart’s presentation. You need a brass rod and some valve lapping compound. I have not yet tried final fitting of the male, but I don’t plan to buy a Sunnen hone. Oct. 9: I have had some feedback warning against the use of lapping compound on copper alloys. Note that Bogart laps with Clover Compound (carbide), which he considers to be non-embedding. Still, not everyone in the business thinks that lapping is a good idea for ferrules.

Slitting: Somebody needs to invent a fixture for doing this on the lathe. Sherline P/N 2045 (index block) might be part of this fixture.