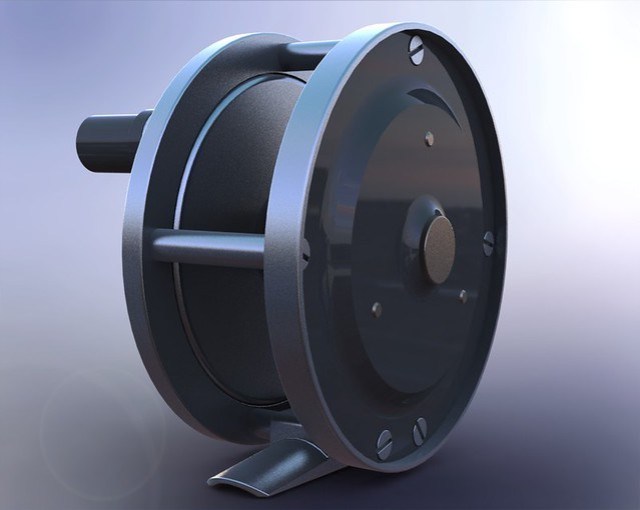

For some time, I have been plotting how to make a one piece spool. My spools so far have been assemblies. The difficulty is the limited power and size of my Sherline lathe and mill. Recently I am developing a design for a very small reel, and this seemed like a good place try the first one piece spool. Here is my procedure.

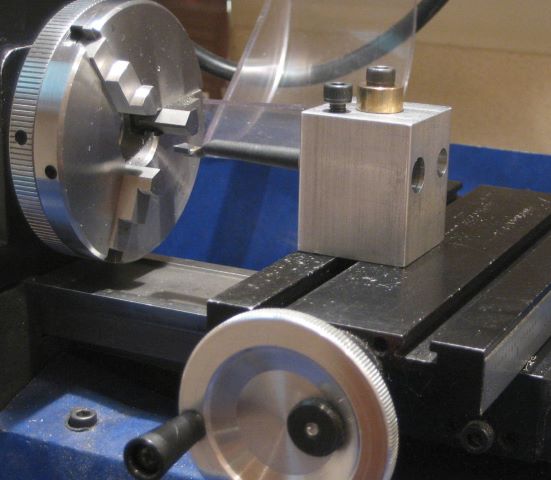

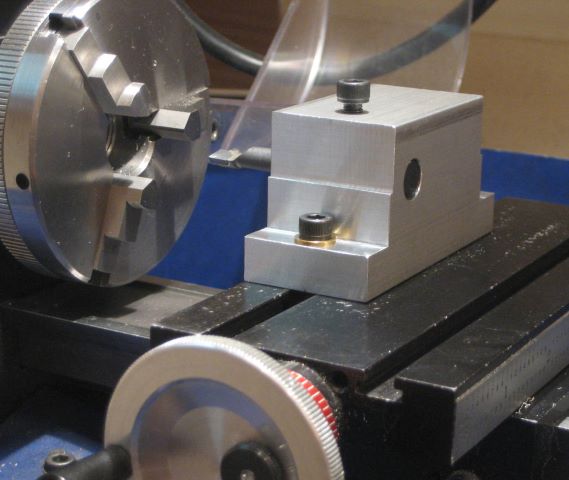

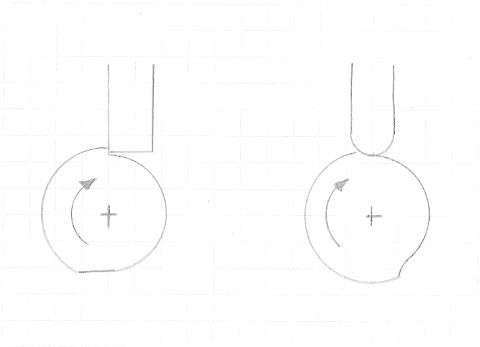

Starting with a section of round rod, face both ends. Drill and bore a through hole so that the material can be clamped to a faceplate (on the lathe) or to the rotary table (mill). Cut the OD at both ends and add any recess details.

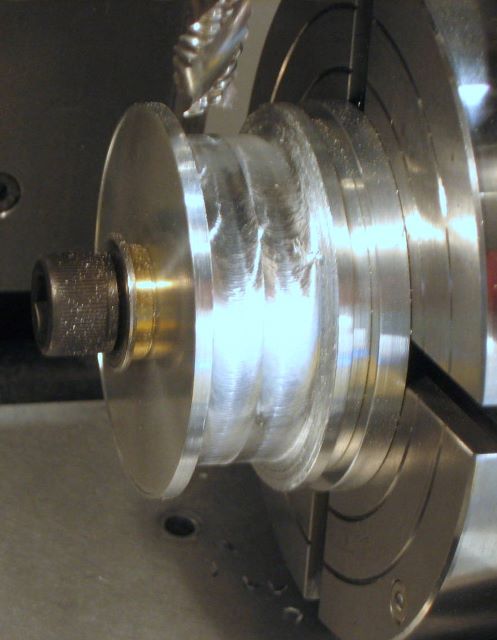

With the work clamped to the rotary table and the table in a vertical position, remove as much material as possible with a roughing end mill.

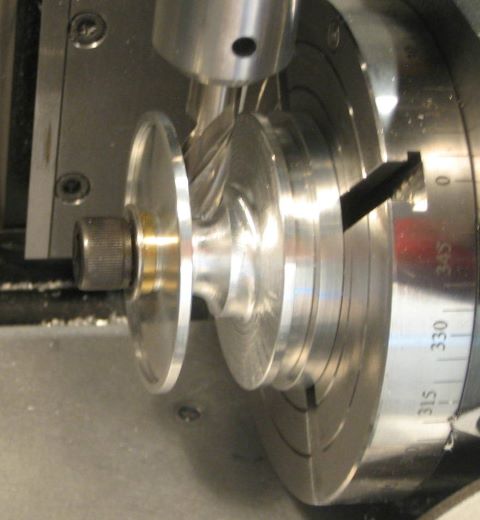

Switch to a ball end mill and continue removing material from the center. Leave some material for finish turning.

When using a square end mill, offset the spindle from the rotary table axis. A ball end mill can be run on center.

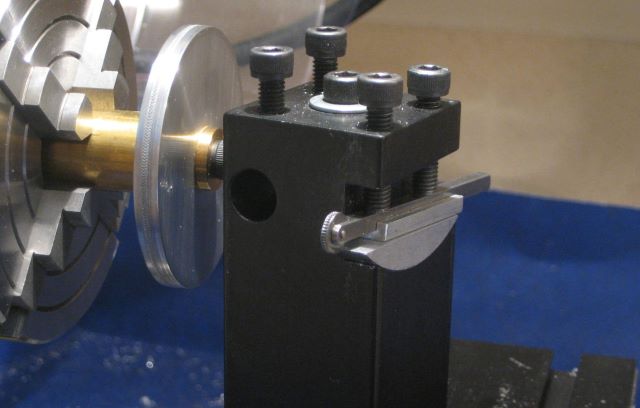

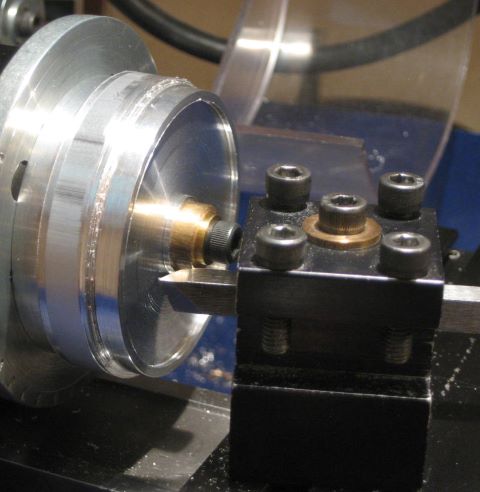

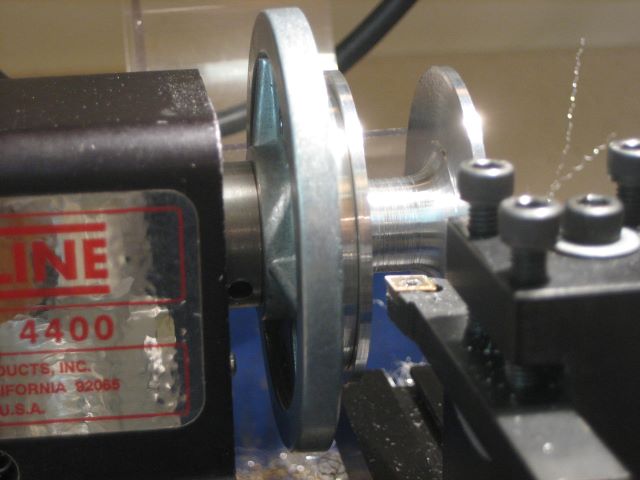

Finish turn the flat areas of the ends with a carbide insert tool. I can find no way to get an HSS cutter into this space.

The deepest turning is done with this custom tool post. It uses a 3/8 inch diameter carbide insert.

Here is the finished spool (not yet ported or anodized). This was less difficult that I anticipated.

The raw material weighed 5.6 oz, and the spool (not yet ported) weighs 0.85 oz. So 85% of the material was turned into chips.