A feature of my new “HiTorque Mini Mill” is that the column (supporting the head) CANNOT be tilted to allow drilling at an angle. This lack of tilt is a positive feature because it means that there should be no way for the head to get out of alignment (i.e., tilted).

I have lived for several years with an out-of alignment mill, my Sherline. I could bring it into alignment (in the X-Z plane) by loosening 4 screws and re-tightening them while pushing the column to one side. But the limited frictional grip of four 10-32 screws and the overhung weight of the mill’s motor meant that in a short time, vibration would work it back out of alignment. So milling cutters in X direction motion were working on one edge and there would be relatively deep milling marks to be sanded out. The flat surfaces of a reel foot needed a lot of manual work.

The new mill, as delivered, cannot be expected to be in perfect alignment. But the mill column is bolted down to 4 machined pads on the mill base.

So when appropriate shims are placed on each pad, the column’s inherent tilt can be corrected in both the X-Z plane and in the Y-Z plane. And it should stay corrected.

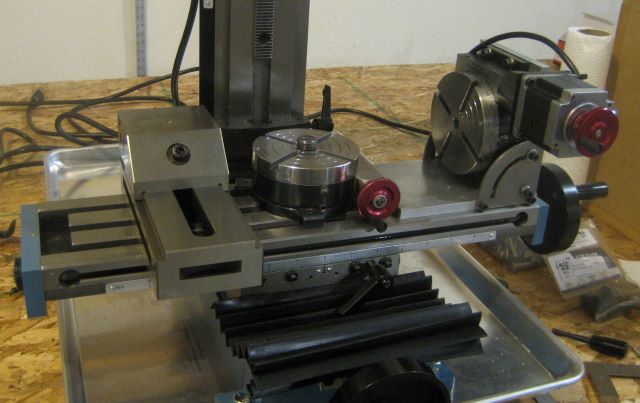

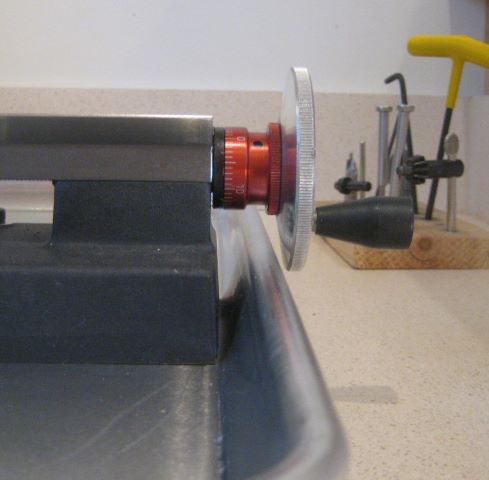

I made a fixture to support a dial test indicator from the mill spindle. This is the first thing that I have made with the new mill. 130 pounds of cast iron runs very smoothly.

With this fixture, I found that the table was out of level in the X direction by .012 inch over a 14.5 inch span, and out of level in the Y direction by .005 inch over a 4 inch span.

By simple proportions of the measurement spans to the mill column bolt stances, I calculated the I needed (ideally) .0044 inch shim for the X direction (side to side) and .0025 inch shim for the Y direction (front to back).

I had on hand brass shim stock of .001 and .005 thickness. So I made 6 shims, 2 at .005 and 4 at .001 thickness. Perhaps .005 and .002 will be “close enough” to .0044 and .0025 .

I punched the holes using a scrap of plastic as an anvil, and this wrinkled the shims. No problem; they will flatten out again under pressure from the bolts. The 4 corners of the mill column got .005, .007, .002, and .000 total shim. I could work the shims into place by loosening all 4 columns bolts, removing one bolt at a time, and tilting the column as required to create gaps for shim insertion. A wooden pencil served as a drift to pull the shims into position.

When I re-tightened the bolts, I found the table to now be level within .001 at all corners. This result is beyond my expectations.